Wingfoil Alu Modular

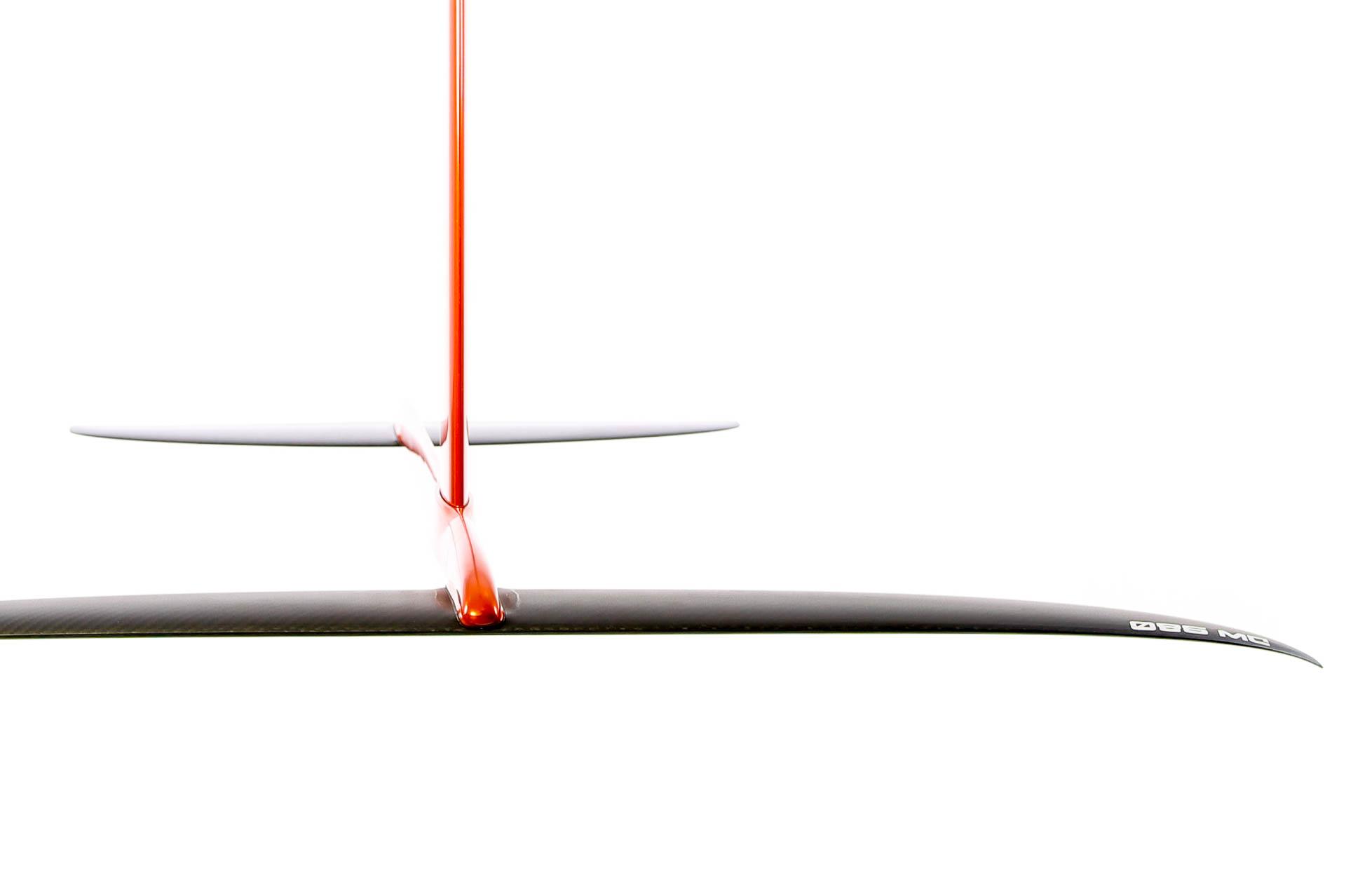

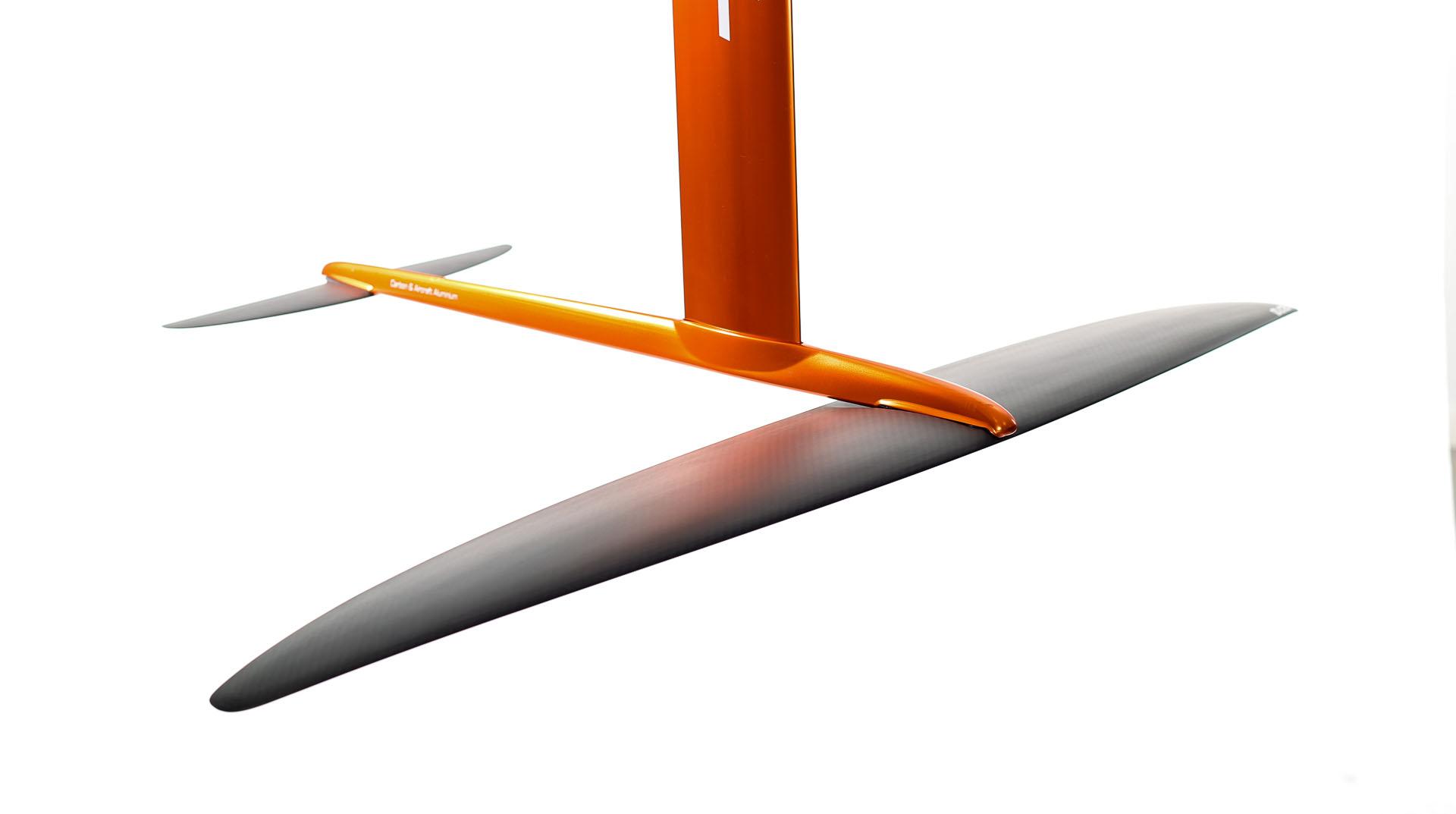

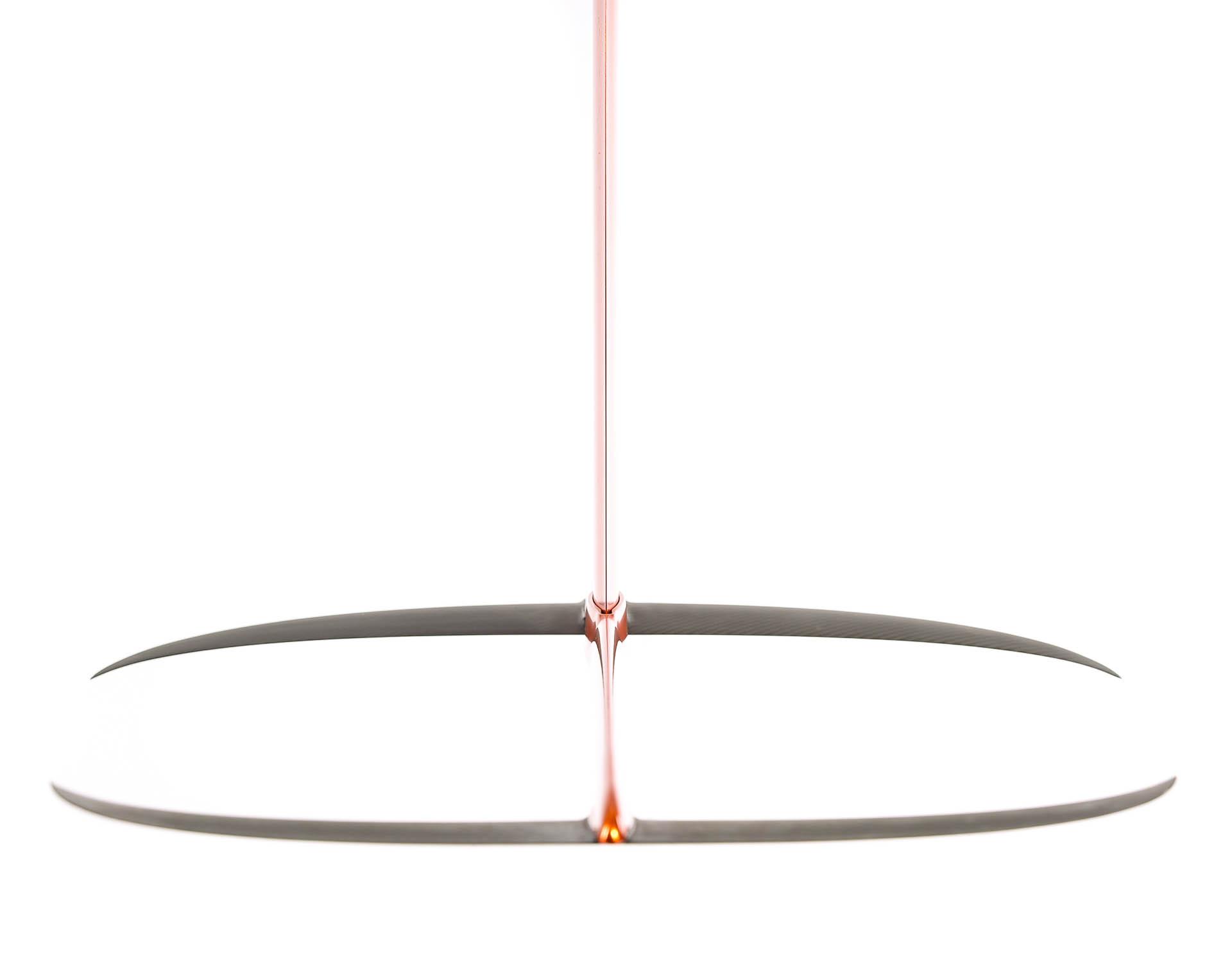

AlpineFoil MODULAR – a Wingfoil made in France without limits and without compromise, the new generation of foil has arrived!

100% upgradeable, it protects your budget while taking into account all the new foil practices and their constraints.

WINGFOIL / KITEFOIL / SUP FOIL / SURF FOIL / WAKE FOIL / PUMPING

Ultralight / Made in France

Beginner to expert level

From Monday to Thursday: 8 AM - 12 PM, 2 PM - 7 PM. Friday: 8 AM - 12 PM

Availability: En stock, livraison rapide

PROMO < 1ER MAI

1 299.00€ inc. tax 1 199.00€ inc. tax

reduction of 100.00€

Wingfoil Alu Modular

Tests and Reviews

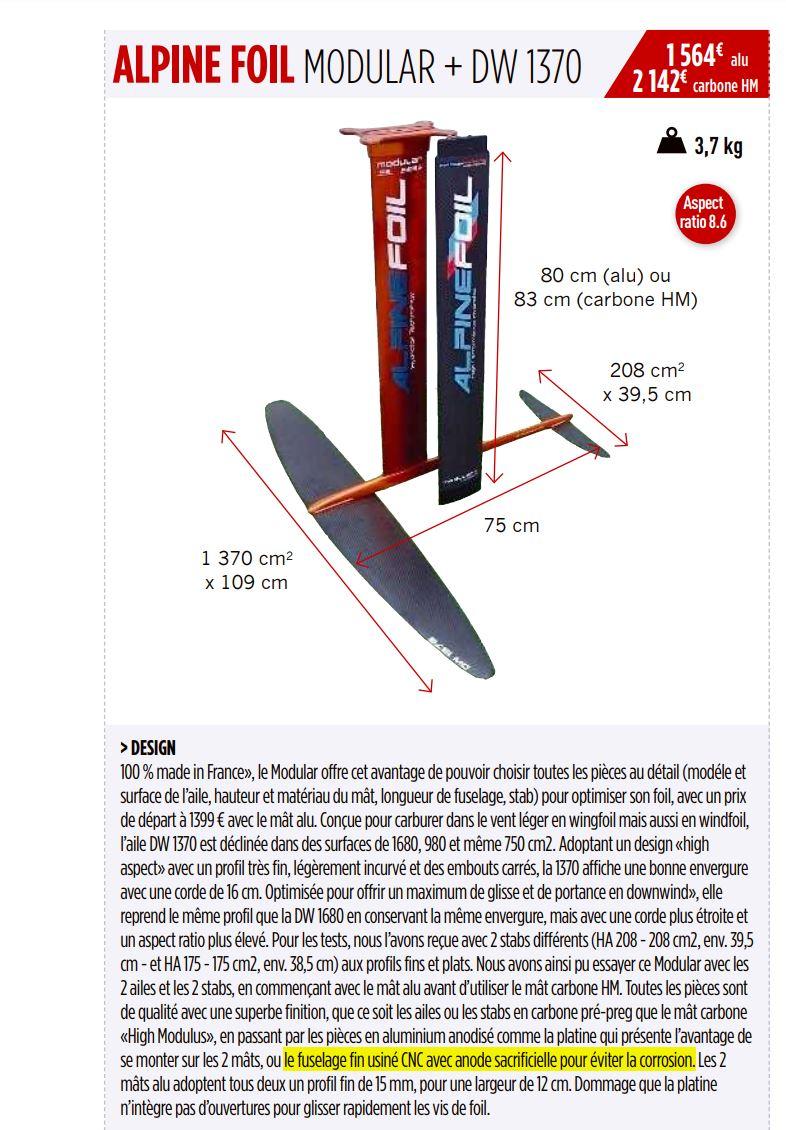

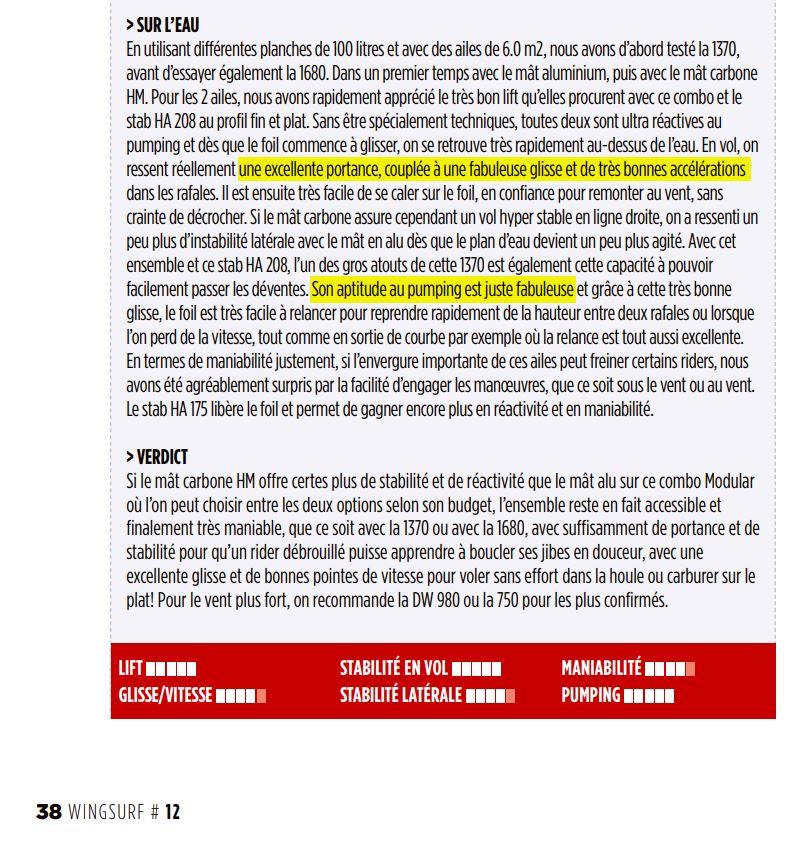

WingFoil MODULAR, Innovation MADE IN FRANCE

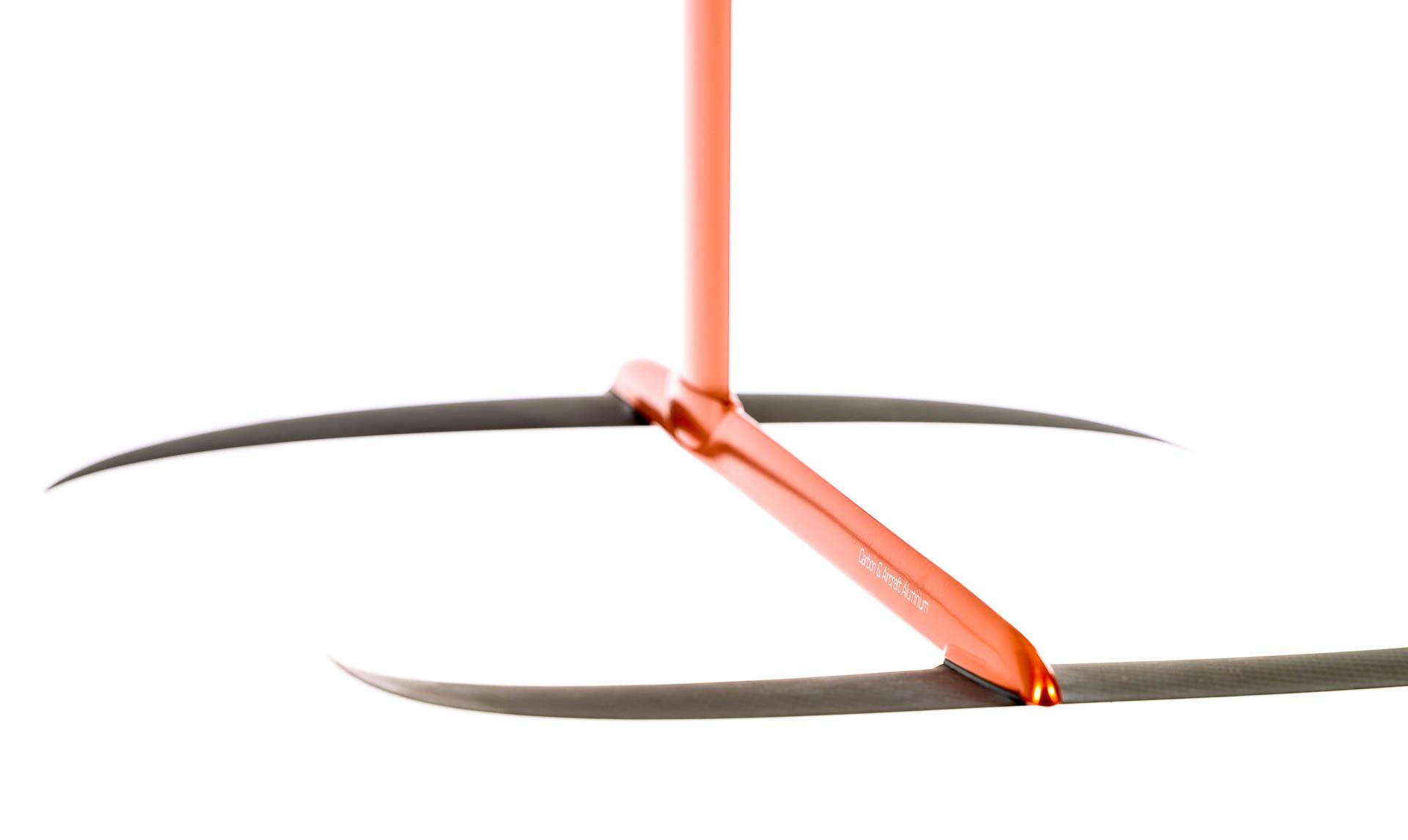

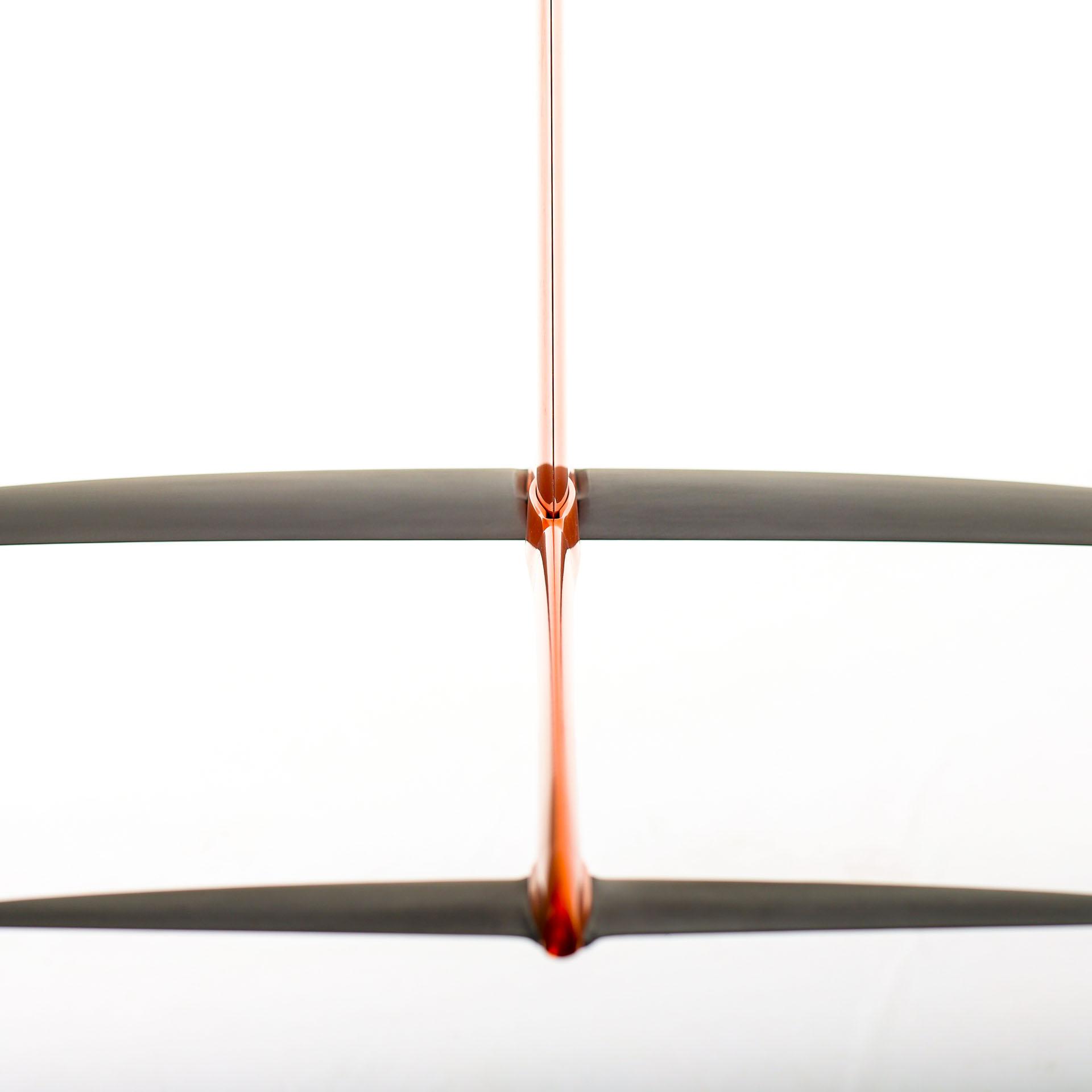

The Fuselage

"Modular" isn't a random name

Front wings for Wingfoil

Recommended

-

M6 M8 T-Nuts US Rail OPTION

T-Nuts M6 & M8 (not supplied) compatible for US Rail self-locking screws Quantity : x4 Compatible...39.00€ inc. tax

Details -

Kitefoil Torx driver tool

Torx mounting compact key, allowing an optimal tightening of the elements of your foil, this key ensures...17.50€ inc. tax

Details -

SIDEON Foil Case - 115 cm x 30 cm

"Suitcase" type cover 115 cm x 30 cm specially designed for foils with plate (HAWK / MODULAR...119.00€ inc. tax

Details -

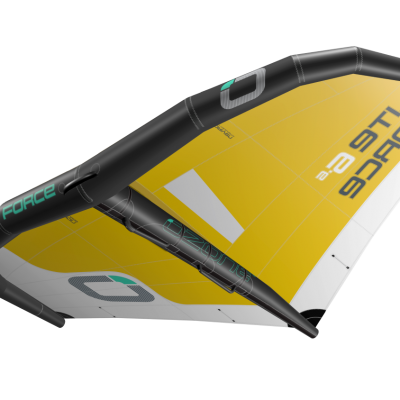

Wingfoil sail - OZONE Fly V1

The Fly V1 is an Intermediate wing that is also perfectly accessible for those new to this sport. We...From

Details

789.00€ inc. tax -

Wingfoil sail - OZONE FLOW

The new Ozone Flux V1 made a dominant release, with Ozone team riders Johnny Heineken and Ken Adgate...From

Details

1 049.00€ inc. tax -

Wingfoil sail - OZONE LiteForce

The Ozone LiteForce is the perfect wingfoil for ultra-light wind conditions. It is available in sizes...From

Details

1 499.00€ inc. tax -

Stabilizer Wing Bag SIDEON 50x15

Stabilizer cover Size 50x15 ideal for Standard Wing, Performance , SHA239 and SHA188 stabilizers allow...34.00€ inc. tax

Details -

Front Wing Bag SIDEON 95x25

Wingfoil/Windfoil compatible foil cover Size 95x25 fits DW980 / DW750 / Regata 850 / Cruise...42.90€ inc. tax

Details -

Foil wing cover SIDEON 115x25

Wingfoil/Windfoil compatible foil cover Size XL 115x25 ideal for DW1680 , DW1370 and Regatta 1100 High...42.90€ inc. tax

Details -

Wingfoil Rake shim

Rake adjustment shim for US Rail system, allows to optimize the take-off of the foil in the light wind...26.00€ inc. tax

Details -

Carbon Mast Modular 83

83cm - 100% Carbon - KFBox / 4 Hole Plate (Sold Without Box) Kitefoil / Wingfoil Carbon mast compatible...689.00€ inc. tax

Details -

HM Carbon Mast Modular

HM Carbon Mat (High Modulus Carbon) - 100% Carbon - KFBox / 4 Hole Plate (Sold without Box) Kitefoil...From

Details

874.00€ inc. tax -

Pack Short Mast 65 cm + Foil -30%

65cm 100% Aluminium - Kitefoil/Wingfoil (Sold without box) The main function of a short mast is to...285.00€ inc. tax

Details -

80CM MAST OPTION -30% Foil + Mast Purchase

80cm 100% Aluminium - Kitefoil/Wingfoil (Sold without box) Aluminium mast for Alpinefoil Modular, length...0.00€ inc. tax

Details -

LONG MAST 95CM OPTION -30% Foil + Mast Purchase

93cm 100% Aluminium - Kitefoil/Wingfoil (Sold without box) Aluminium mast for Alpinefoil Modular, length...0.00€ inc. tax

Details -

WG89 BOARD OPTION -100€ Foil + Board Purchase

Planche Wingfoil WG89 , 4.9 x 27.5 - 89 litres - Programme : Confirmé à Expert, construction...1 499.00€ inc. tax

Details

Questions / Answers

Add a comment