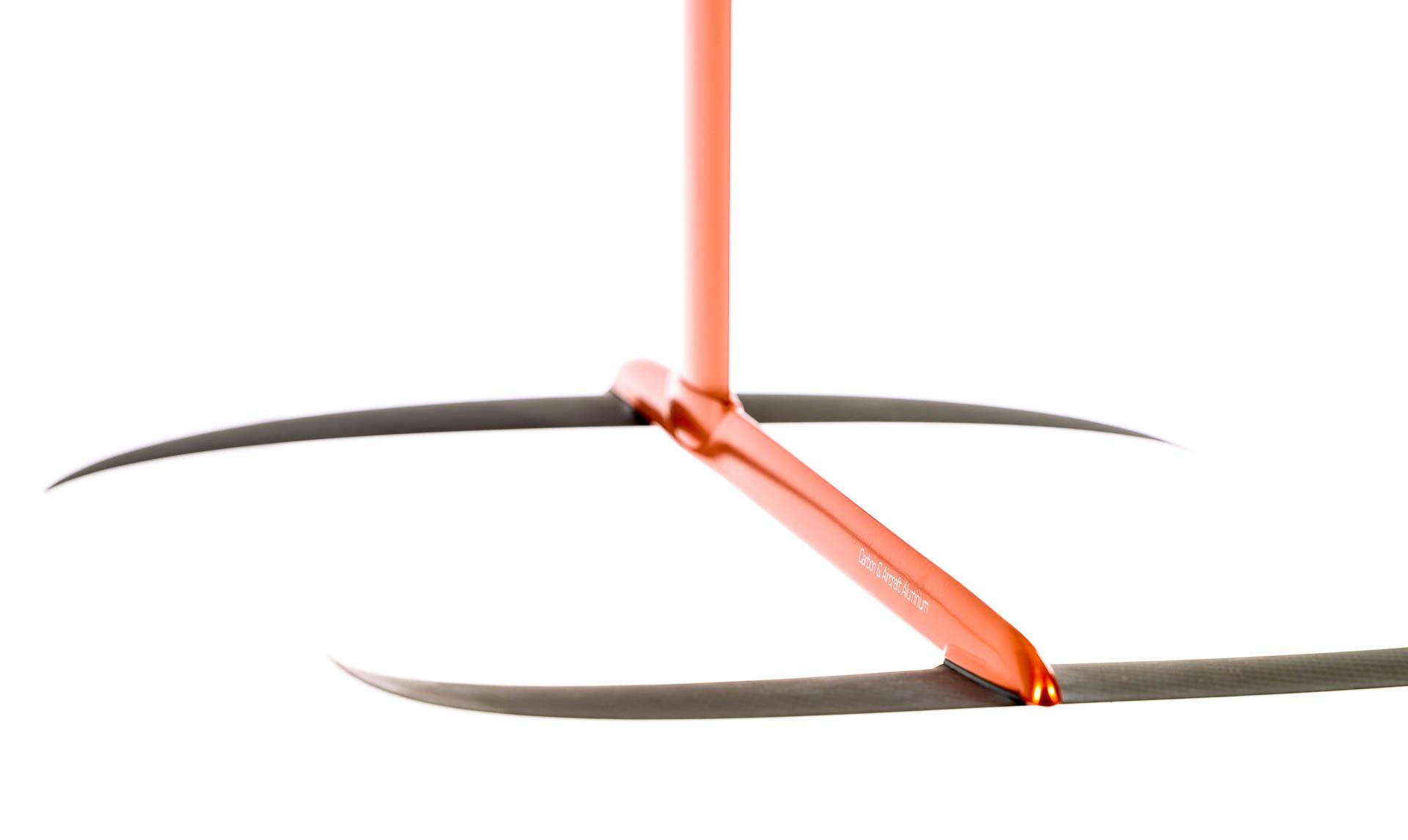

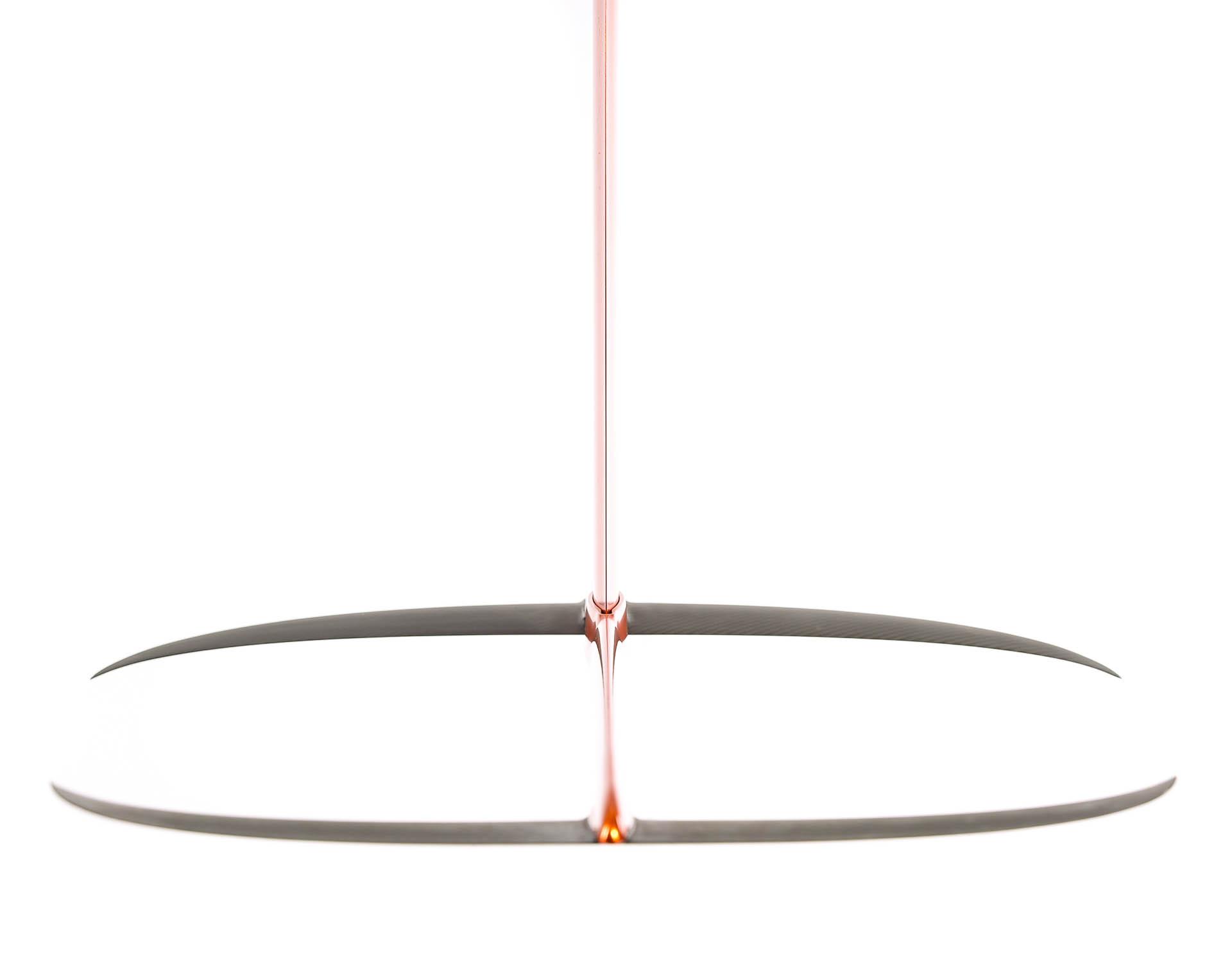

For the MODULAR we started from a blank sheet, and we decided to lay a whole new foundation for this foil.

The foil has revolutionized water sports, it has exploded in recent years with a multitude of practices: Wingfoil, kitefoil, Surf foil, SupFoil, Pumping, Wakefoil, ...

The observation is simple, we are for the most part, become multi-support and our budget is not extensible.

So why not start with a blank sheet and design a modern, modular foil that would take all these practices into account, while laying new foundations for design?

- Mechanical

- Performance

- Weight

- Flow optimization

- Budget

Initially, Alpinefoil is a mechanical and composite design office with Alpine Design and DCE Engineering,

our specialty is to design, invent, innovate, find solutions and manufacture foils in France for everyone and for all as well as for other companies in the world of sailing.

Since 2007 Alpinefoil designs foils and the company has been awarded several times for its innovations: in 2013 with the ARTINOV prize, in 2014 with INOSPORT and in 2020 by ALPES IS HERE

In 2013 Alpinefoil designed the first standard Aluminium kitefoil in order to lower production costs and democratize the practice, 6 months later the first Titanium/Carbon mix kitefoil appeared solving corrosion problems, and mechanical resistance for the most demanding.

In 2016, Alpinefoil added to its aluminium foils a sacrificial anode that improves the corrosion resistance of aluminium foils. 2016-2017-2018 Alpinefoil is French kitefoil champion on the Engie Kite Tour.

In 2017 Alpinefoil developed a ROBOT head for sanding during foil production.

In 2018 the first Winfdoil A1 appeared with a new approach on the accessibility of the Windfoil.

In 2021 Alpinefoil create the first kitefoil Pocket board built as a foil wing with a weight of only 1.9 kg and an outstanding stiffness.

Since 2007 we have acquired a thorough knowledge of the Hydrofoil wing profiles, which allowed us to push back the low and high beach of the foils.

2022 Version 3 of the robotic head is functional.

Our mastery of ECO Design is reflected on, the design and manufacture of our foils including our moulds and packaging, which allows us to guarantee a MADE IN FRANCE quality respectful of the environment.

Many of the AlpineFoil innovations were taken up and the foil was made accessible to as many people as possible.

Today with the MODULAR everything has been revised, only the orange color dear to Alpinefoil, the passion for sliding and technique have been preserved.

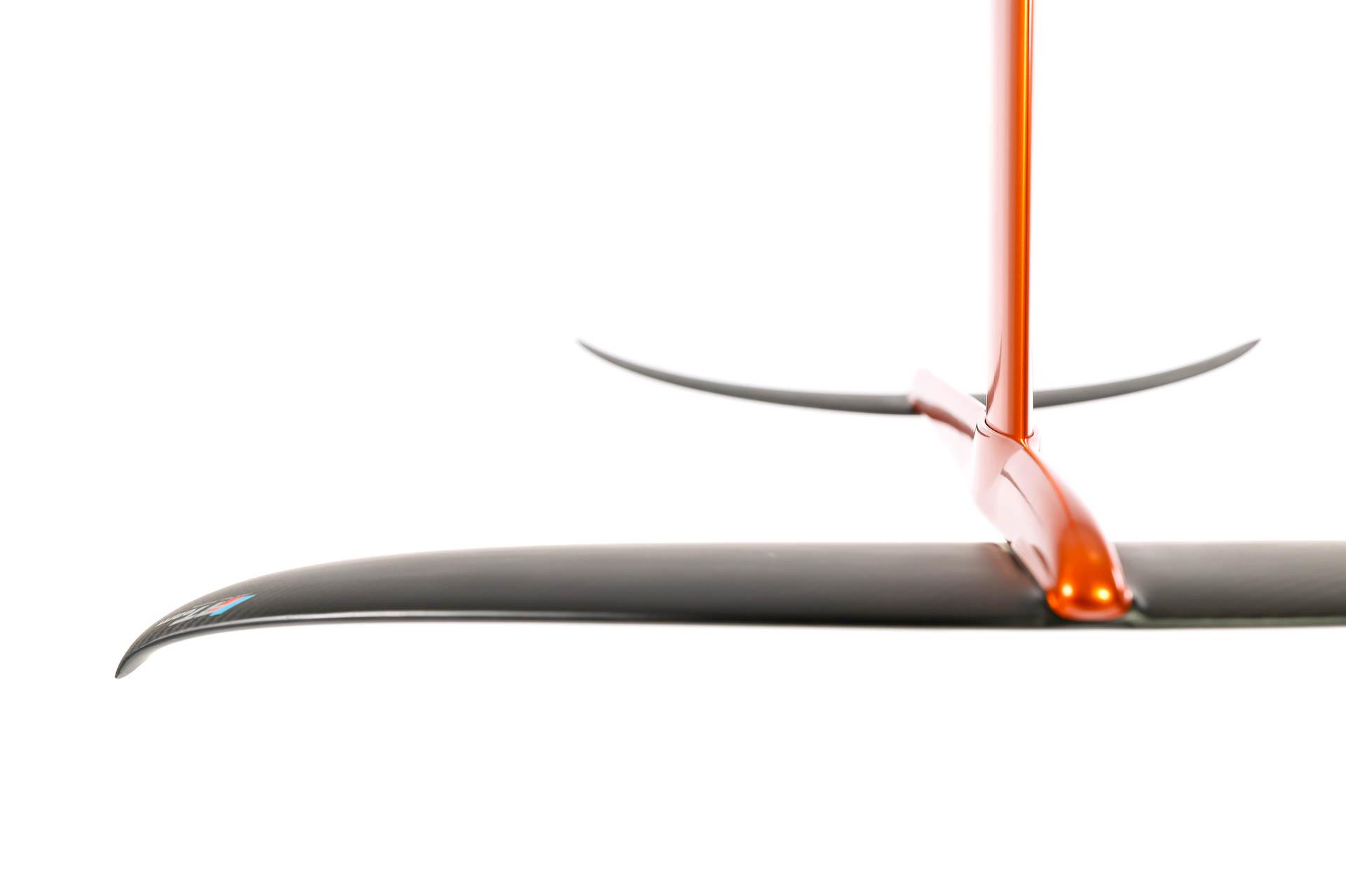

THE MAST

The First point and one of the most important is the Mast, the current aluminum mats are very poorly suited for Wing/ Surf/ Sup ..

They are often too heavy, too flexible, too fragile, too inefficient, or penalized by the ventilation that throws us to the ground and prevents us from enjoying our foil serenely.

The second point is the Glide, a lot of people come from the Windsurf, the Windfoil, or the Kitefoil.

Currently the support that brings the most performance and glide is the kitefoil but today the wingfoil has totally mutated.

What we are looking for is to find the glide that we have in kitefoil but adapted to the Wing and has its constraints.

It was therefore logical that our experience in designing kitefoils is found in this new mat.

The goal for us is to find the gliding sensations of the Kitefoil and Windfoil but in Wingfoil.

- Scalability despite obsolescence

Moreover, aluminium mats are rarely scalable: it is impossible to replace the aluminium profile with a carbon profile, because the method of fixing a carbon profile must be different from that of an aluminium profile.

For this reason, in the foil market, in order to evolve its foil aluminium to a carbon foil, there are rarely other possibilities than to replace the mat, the plate and sometimes even the fuselage, which widens the financial gap of this development well above the 1000 euros.

On the Modular to evolve its foil with a carbon mat costs only: 629 euros.

When we know that 70% of practitioners want to eventually evolve towards a carbon mast, we think that this possibility is financially interesting.

Coming back to the Modular aluminium mast, we had several problems to solve during its design:

Problems of weight, stiffness (use of foil wing with large weights) and ventilation (sudden stall of the mast in navigation).

We had to draw a whole new profile.

This started with a flow study, then with RDM (Resistance of Materials) modelling to optimize the internal structure of the mast in order to obtain the best mechanical performance in torsion/bending

But we decided to go even further on this mast.

The majority of extruded foil mats use relatively standard aluminum found on porch profiles and other window doors. This aluminium has the particularity of offering a good quality/price/performance ratio.

But by studying more closely this aluminum alloy, we realize that it remains nevertheless quite malleable.

There is therefore no other solution than to increase the thickness of the profile and thus the weight.

On the Modular we have chosen to use an aluminium alloy found in cycling or aviation and which brings a very important gain in rigidity and consequently a much better control of the foil.

This ultimately gives us a lightweight aluminium foil where everything has been optimized, down to the smallest detail.

- A polishing for the Slide!

During the extrusion process of the aluminium profile, the tooling leaves traces on the raw profile.

To remedy this, the simplest technique is to sand the profile by projecting fine microbeads, this makes it possible to remove these small defects, but generates a slightly grained and rough surface state that alters the glide.

We have decided to polish before the anodizing of the mast in order to optimize the foil’s glide and push its performance even further.